Promoting the next generation of agricultural machines

The Gantry Tractor - farming's soil mate!

Twice the profits, half the cost

The gantry provides a stable platform for high precision and part-width operations which not only cuts down on chemical use and power demand, but permanently liberates 90+% of field areas from soil compaction damage. It also allows us to introduce, for example, strip-intercropping, with its associated reductions in pest and disease pressures and increased biodiversity. The machine can be scaled to any width and is equally suitable for small grassland farms as for very large arable enterprises.

Read on to find out more

An all too common concern for farmers these days is the damage heavy machines are doing to their soils. Despite careful planning and the use of innovative technology, repeated traction over valuable farmland causes soil damage to ever-increasing depths. Trying to restrict this to as small an area as possible is what we all aim for (called “controlled traffic farming” or CTF), but current technology doesn’t do the trick. Cue the Gantry Tractor… farming’s new generation wide-span soil protector.

The wide-span concept has the potential to cut by half the energy cost per tonne

of food produced, while doubling farmer’s profits. It protects against unnecessary soil damage and is perfectly suited to automation and to work with plant-scale robotics.

The gantry provides a stable platform for high precision and part-width operations which not only cuts down on chemical use and power demand, but permanently liberates 90+% of field areas from soil compaction damage. It also allows us to introduce, for example, strip-intercropping, with its associated reductions in pest and disease pressures and increased biodiversity. The machine can be scaled to any width and is equally suitable for small grassland farms as for very large arable enterprises.

As such, the gantry tractor is an advanced technology capable of providing environmentally friendly crop production with maximum efficiency and minimum risk to the soil.

Background

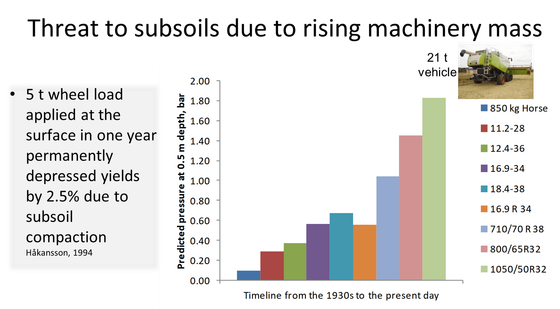

Over the past 50 or so years, the size and weight of agricultural machines has grown immensely. We have now reached the point at which (despite improvements in tyre design and the introduction of rubber tracks), subsoils are being stressed beyond their historic equilibrium. This change has negative consequences in terms of drainage characteristics and is often uneconomic to repair.

Of equal concern is the damage to topsoils, which is almost impossible to avoid all of the time - the traffic associated with minimum tillage systems in particular creates severe compaction just below tillage depth. Crops like potatoes and sugar beet, which are often harvested in conditions that are far too wet, cause immense concern for the health of our soils.

In response to these worries, farmers have started to adopt controlled traffic farming (CTF) systems. These confine soil compaction to the least possible area of permanent traffic lanes (see www.controlledtrafficfarming.com

for more information). Although this doesn’t get rid of compaction altogether, it does confine it to a much smaller area, perhaps just 15% compared with the 40%-85% or more associated with traditional systems. However, this 15% can only be achieved by the largest machines, i.e. 10 m wide or more and once established, the systems are very inflexible in that only one width of operation is possible. The gantry tractor overcomes this problem and also tracks smaller areas. For example, a nominal 5 m wide machine may only track 8% of a field area, while a 10 m machine could achieve just 5%.

What is a gantry tractor?

A gantry tractor can best be described as an agricultural vehicle whose wheels or tracks are separated by a "greater than conventional distance" in its field mode, as shown above and alongside. The wheels can be turned through a large angle that allows the vehicle to be driven lengthways on the road.

Implements are normally mounted between the pairs of wheels but don't need to fill all the space between them, i.e. the gantry can work with part width implements. If the implement doesn’t touch the ground (i.e., it’s got a "boom"), it can be much wider than the machine, i.e. a 10 m gantry could have a 40 m wide spray boom.

What does a gantry tractor do?

A gantry tractor can do all the things that a conventional tractor can do, but in a more precise and controllable manner. It also tracks less than 10% of field areas by using each wheel track twice, i.e. the wheels at one end run in the track of the previous pass. With conventional systems, field headlands are extensively tracked by wheels, as illustrated in this video. Compare this with the operational finesse of a gantry tractor system which tracks only a marginally greater area on the headlands than it does in the body of the field. This video

shows just how it works and is scaled to reality, both in size and speed of operation.

The other advantage of the gantry is that it sets out a grid pattern in the field that can be followed during subsequent operations. Although this allows the driver to steer accurately, satellite navigation and auto-steer are also used to improve precision and relieve the driver of constant steering corrections. However, failure of the navigation system does not leave the driver “high and dry” as it might with traditional equipment, he or she can still keep to a very visible traffic lane!

Why is a gantry tractor considered to be better than a tractor?

In a nutshell, because it offers enormous opportunities for a positive step change in production efficiency while cutting damage to soils to an insignificant amount.

Put it this way, if there was a practical and cost-effective mechanisation system that eliminated soil compaction damage from 92+% of field areas and raised farm profits sustainably, should we use it? Logic says we should and particularly at this time when there is an urgent need to conserve the world’s resources and sequester carbon in the soil. The gantry tractor system is poised to take over from existing practice needing only passion and foresight to take it forwards.

Put it this way, if there was a practical and cost-effective mechanisation system that eliminated soil compaction damage from 92+% of field areas and raised farm profits sustainably, should we use it? Logic says we should and particularly at this time when there is an urgent need to conserve the world’s resources and sequester carbon in the soil. The gantry tractor system is poised to take over from existing practice needing only passion and foresight to take it forwards.

The gantry has a whole range of advantages compared with today’s conventional practice and not just those associated with soil protection. These benefits are summarised under different categories below but dealt with in more detail under "BENEFITS OF THE GANTRY TRACTOR”, but here they are in as small a "nutshell" as possible!

Benefits for the food producer (farmer/grower)

- minimum of 35% reduction in crop establishment costs

- lower operating costs

- reduction in capital investment

- increased crop yields

- ability to plough without compromising the CTF system

- greater potential for timely field operations

- reduction in the area of wheel tracks in the field

- improved soil health

- less costly implements

- less costly prime movers

- built-in guidance system

- lower chemical costs due to an inherently more stable vehicle

- improved plant available water in periods of drought

- improved quality of field-dried forage and efficiency of harvesting

- ability to avoid subsoil damage when creating crop beds

- more flexible and sustainable organic farming systems

- high level of machine stability and compensation for down-slope or side slippage

- ability to deal with offset loads, including part width ploughing

- more flexible weed control

- ability to strip inter-crop at sub-bed level

- soil repair without subsequent compromise

- competitive edge associated with a completely revised agricultural mechanisation

- lightweight & novel implements

- stable platform for increased precision

- opportunity to get into the harvest machinery market

- integrated & precision control systems

- revised crop harvesting machinery

- greater opportunity for automation

- a universal prime mover appropriate for soil and crop care as well as harvesting

- reduced impacts on the quality and cost of water treatment

- diminished precursors of carbon dioxide emissions

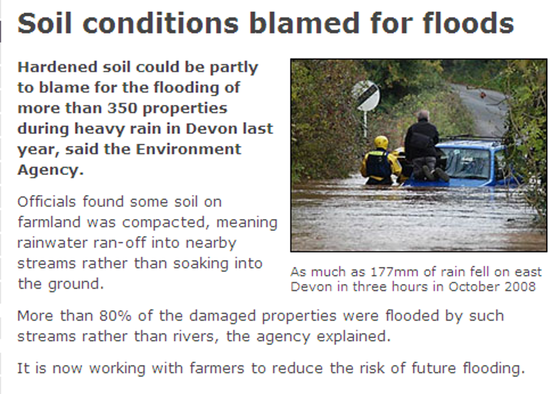

- lessened risk of flash flooding

- improved consistency of food quality at little or no extra cost

- reduced use of chemicals

- lower cost for organic produce

- nutritious food at affordable prices produced with environmentally safe methods

- improved quality and consistency in the raw product

- reliability of supply

- sustainability of supplier systems

- superior product image

- additional fuel saving compared with traditional CTF

- maximum potential for carbon sequesration

- less chemical applied due to more precise targeting

- less soil, chemical, organic matter and nitrous oxide lost from field systems due to improved soil health

- diminished precursors of carbon dioxide emissions

- less water run-off and risk of flash floods during periods of intense rainfall

- improved soil biodiversity due to less soil manipulation

- increased close-scale crop diversity